One fleece, many futures

Every spring, when shearing day arrives at the farm, I’m left standing in the barn surrounded by soft, shining piles of fiber—each one as unique as the alpaca who grew it.

To some people, it all just looks like “fleece.”

To me, it’s the beginning of a long decision-making process.

Because every clip doesn’t become the same thing. Some fleeces are destined for yarn, others for roving, some are kept intact as lustrous suri locks, and some are best suited for hand processors who love working fiber from the very first wash.

So how do I decide?

Let’s walk through what happens between shearing day and the finished fiber you see at our booth—or in your project bag.

First: Meeting the Fleece Where It Is

As soon as an alpaca is shorn, we start evaluating:

Micron & handle – How fine does it feel? How soft is it against the skin?

Staple length – Are the locks long and flowing or shorter and springy?

Uniformity – Is the fleece consistent throughout or more variable?

Strength & density – Will it hold up to processing?

Suri alpaca fiber—what we raise here on our farm—is especially known for its luster and drape, but even within suri, no two fleeces behave exactly alike.

Some practically glow the moment they hit the skirting table. Others have wonderful character but more texture or variation.

None of that is bad.

It simply points us toward the right end use.

When a Fleece Becomes Yarn

When a clip is especially fine, uniform, and strong enough to handle full milling, it may be selected for yarn.

Some of that fiber becomes 100% suri alpaca yarn on cones—the foundation of our upcoming Harvest Knitwear Collection. These cones are produced with machine knitting in mind, allowing us to create farm-grown garments from our own alpacas, start to finish.

Other fleeces are blended with merino and spun into skeins, becoming our signature sport-weight yarn. The merino adds elasticity and bounce, while the suri contributes its unmistakable luster and drape—a combination we’ve come to love for hand knitting and weaving.

In both cases, these fleeces represent some of the very best of what our herd grows: consistent, beautiful fiber that’s carefully matched to the final product we have in mind long before it ever leaves the farm.

When a Fleece Becomes Roving

Roving is often our go-to when a fleece is soft and lovely but better suited for spinners than finished yarn.

We’ve learned that even fleeces with very similar micron counts can behave differently once processed.

Some come back as smooth, even roving—a spinner’s dream.

Others are processed in a more rustic style, sometimes including tiny neps or variations that create wonderful texture and visual interest in the finished yarn.

Both are 100% suri alpaca from our farm.

Both are milled in the USA.

They’re simply… different expressions of the same fiber.

And for spinners, that difference is half the fun.

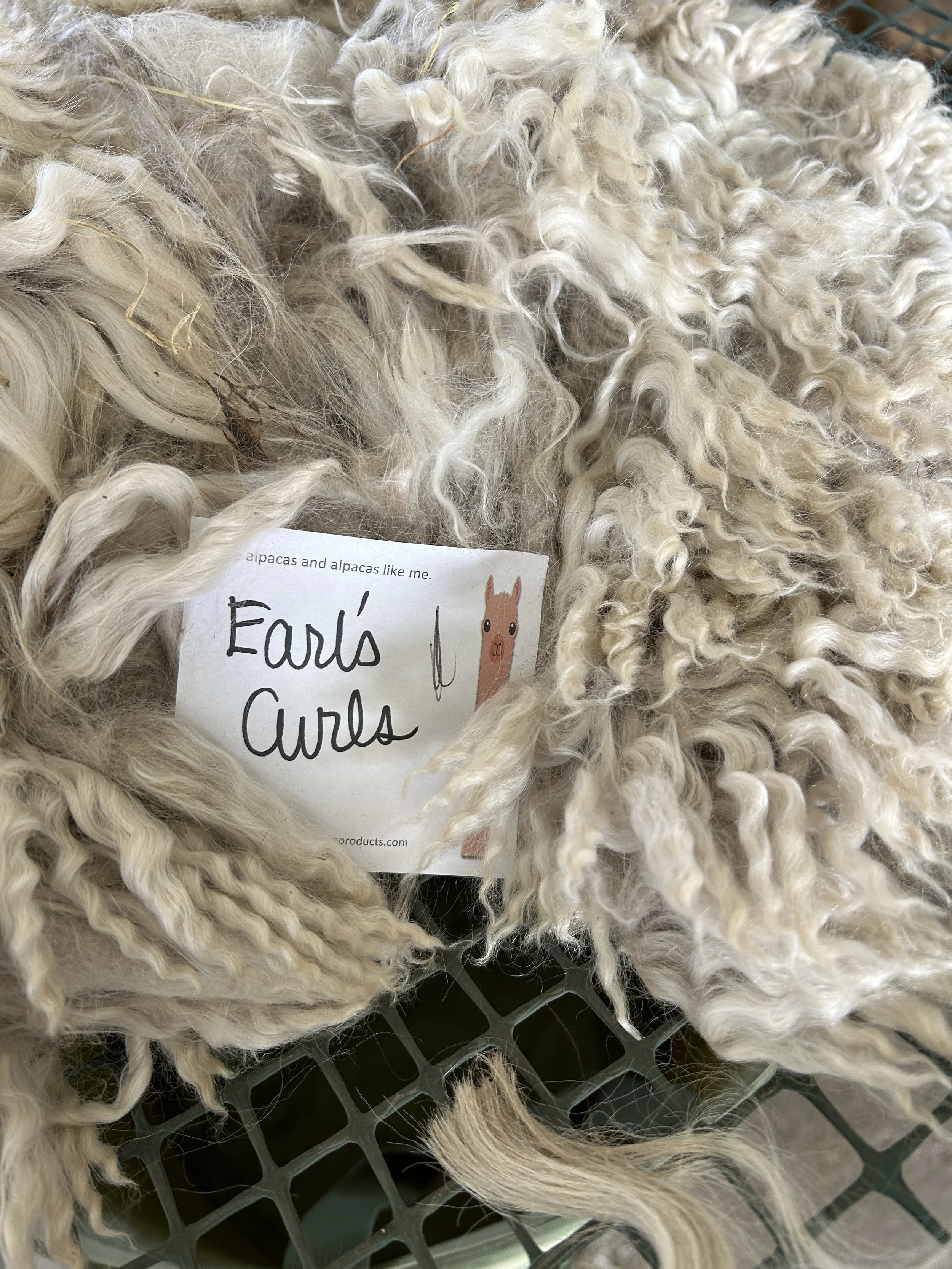

When We Keep Locks Intact

Occasionally, a fleece is so lustrous and beautifully structured that we set portions aside as whole suri locks.

These long, flowing staples are favorites for:

lock spinning

doll hair

felting accents

art yarn

display pieces

Keeping locks intact takes extra time and careful handling, but for the right fiber, it’s worth every minute.

When We Offer Raw Fleeces

Some fleeces are perfect for fiber artists who love to start at the very beginning—washing, picking, carding, and transforming raw fiber by hand.

Offering raw fleeces:

keeps the fiber affordable

lets you control every step of preparation

gives you the chance to truly know an alpaca’s coat from start to finish

We skirt them carefully, label them honestly, and send them along to homes where we know they’ll be appreciated.

What Happens to the “Scrap” Fiber

Not every part of a fleece is destined for yarn, roving, or locks—and that’s exactly how it should be.

During skirting, fiber is removed from the belly and britch areas, along with any sections that are heavily soiled or too coarse for processing. Around here, we call this our scrap fiber.

But that word doesn’t mean worthless.

It simply means it has a different job.

This fiber often finds second lives in wonderfully practical ways:

garden mulch or compost additions

insulation for outbuildings

felting practice

stuffing for draft blockers or pet beds

erosion control in garden beds

nesting material for our feathered friends

soil conditioning once it breaks down

Using these portions keeps waste to a minimum and honors the animal by making sure as much of each clip as possible is put to good use—even when it never becomes something you’d knit with.

On a working farm, sustainability isn’t a buzzword.

It’s just part of the daily rhythm.

The Goal Is Always the Same

No matter what form the fiber takes, our goal doesn’t change:

Respect the animal.

Respect the fiber.

Put each fleece where it will shine.

We don’t force every clip into the same product just because it’s easier.

We let the fiber tell us what it wants to become.

Looking Ahead

Over the coming months, you’ll be seeing more of these pieces—roving, yarn, locks, fleeces, scrap fiber—offered at events like Purlside Fiber Fest, our local farmer’s market, and through our BarnRaiser fundraising efforts as we work to restore our 156-year-old barn.

If you ever stop by our booth and wonder why something is presented the way it is, ask.

We love talking fiber.

It’s why we do this.